| Application | Isolation |

| Features/Benefits |

|

| ANSI class / Rating | 150# |

| Design Standard | MSS SP 81 |

| Testing Standard | NA |

| Size | 100-900 mm NB |

| M.O.C | CS/AISI-304/316/304L/316L |

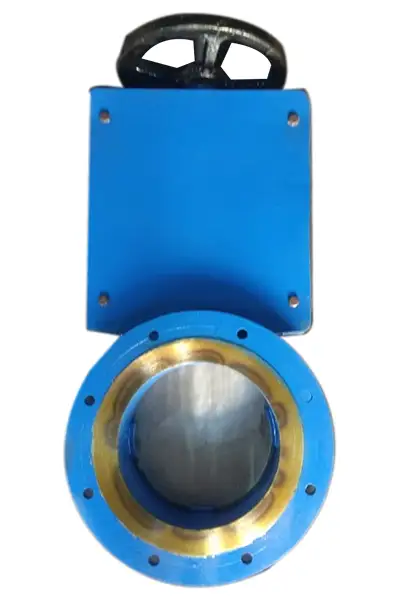

| Ends | Wafer type, square and round flange |

| Operation | Manual, Pneumatic, hydraulic, gear operated, motorized, chain operated |

We also manufacture knife edge gate valves in various MOC and sizes.

The valves are regularly used for applications to handle, pulp in pulp mill, slurries, powder such as coal, ash, dry and wet powder in power houses, pneumatic conveying systems, dust collecting systems and material handling equipments.

For liquid slurries and fiber applications with low-allowable leakage the valves are most commonly used.

Pneumatic, Manual, Gear and hydraulic equipment devices are provided for operation of the valves. For elevated mounting, chain driven valves are also provided.

Square and round end connection flanges or wafer design end connections are commonly manufactured.

To cater customers’ one-one or general requirement, we have codify our products in various item codes. Operation-manual, gear, pneumatic, chain; shape of in-out connections-Round, Square etc & other.